|

|

|

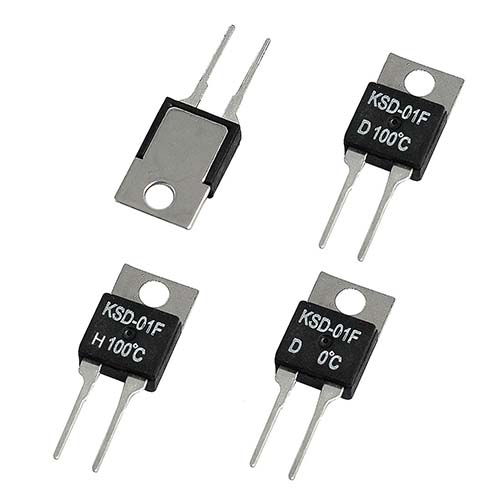

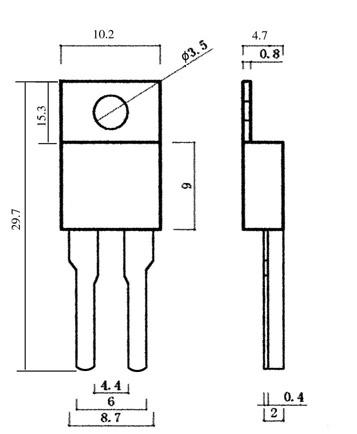

PCB板安裝溫控器KSD-01F

3.1端子 Terminal 鍍銀,無鉛。 Silver plated.Nought of lead

4 基本性能參數 Basic Perfor,mance 4.1 電氣參數 Dielectric Parameter

4.2 溫度 Temperature 4.2.1 溫度特性 Characteristic 例:動作溫度:35±5℃; Operating temperature; 回復溫度:20±15℃; Max temperature restoration,Less than Operating temperature

4.2.2 測試方法 Test mehod 將溫控器安裝在測試夾具上并放置于測試區進行測試。以空氣為熱傳導介質,在測溫去放置溫度計或溫度傳感器。在溫度進入產品動作、回復溫度范圍檢測,應保證升降溫度速率不大于4℃/min,其間必須對測溫區內的空氣進行充分攪拌,使溫度分布均勻:測溫區內的溫度均勻性在0.5℃以內。 During testing,the samples are clamped in the testing zone.Tesing begins when temperature in temperature-measuring zone stays in equilibrium. The testing furnace is filed with air as heating medium,while thermometer or temperature sensor is Placed in temperature-measuring zone.Temperature increases or decreases from the first 3K of named Action temperature at a speed of 1k/min.During testing,air must be mixed up to make the temperature Distribute sufficiently equable.Distributing equality of temperature in temperature-measuring zone must Be within ±0.5℃.

4.3 端子間電阻 Resistance Between Terminals 初始值 Before life: ≤50mΩ; 壽命后 After life: ≤500mΩ; 測試負載:直流6V,10mA。 Tested load: DC6V,10mA。 4.4 絕緣電阻 Insulation Resistance 在標準大氣條件下,采用DC500V絕緣電阻表以額定電壓測試大于等于100MΩ; With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ. 4.5 電氣強度 Dielectric Strength 在標準大氣條件下,采用900V 50Hz的交流電壓施加于引出端與地之間3min,無擊穿、飛弧、閃絡等。 Parts between electriferous components and non-electriferous ones can bear 1000V 50Hz AC current,which is nearly sina wave,for one minute as bearing test.Resulted no breakdown,no flashover. 4.6 使用環境溫度 Ambient temperature range -25℃~+180℃ -25℃ to +180℃ 4.7 接地方式 Method Of Earth 通過溫度溫控器外金屬板與設備接地金屬相連 By means of the metal cup of thermostat connected in the earthing metal part. 5 可靠性參數 Reliability performance 5.1 實驗條件 Test Conditions 環境溫度20±5℃; 環境相對濕度60%~70%; 電源應為額定電壓及額定頻率50Hz的正弦波電源。 在實驗結果不發生異議的情況下,按下述條件實驗亦可; 環境溫度5~20℃; 環境相對濕度45%~85%; 電源為接近正弦波的交流電源。 Ambient temperature: 20±5℃ Ambient Relative Humidity:50%~70% The power supply should be of sine wave,with rated volts and rated frequency of 50Hz. Without discrepancing the result,test maybe implemented according to the following conditions: Ambient temperature vries between 5~20℃ Ambient relative humidity varies between 45%~85%; The power supply should be AC nearly sine wave; 5.2 工作壽命 Working life 5.2.1 測試方法 Test method 將溫控器在額定負載下給以升、降溫進行觸電開閉試驗,最大循環頻率≤6次/min,每開閉一次作為一個周期。產品經過規定次數的耐久性試驗后性能指針應符合下列規定: Power the sample thermostats with rated volts and max current,increase and decrease the temperature to test the opening/closing of the thermostats’s contacts.The max frequency should be 6 times/min,contact keep closed for one second.Then check the performance.

?動作溫度100℃以下對試驗初始值容許偏差再加上±5℃,100℃以上為±5% ?在標準大氣條件下,采用DC500V絕緣電阻表以額定電壓測試≥100MΩ。 ?在標準大氣條件下,采用1000V 50Hz的交流電壓施加于引出端與地之間1min,無擊穿、飛弧、閃絡。 ?Initial value of experient caused by action temperature:<100℃:±5℃;≥10℃±5%; ?With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ ?Parts between electriferous compenets and non-electriferous ones can bear 1000V 50Hz Hz AC current,which is nearly sine wave,for one minute as bearing test.Resulted no breakdown,no flashover. 5.3 耐低溫、高溫和冷熱沖擊 Resistance of Low Temperature、High Temperture,Cold、Heat Strike 將產品試樣置于-20℃的低溫箱中恒溫保持1h,取出放置2h;然后將產品放置于150℃的高溫箱中恒溫保持1h,取出放置2h;最后將產品試樣置于-20℃的低溫箱中恒溫保持0.5h,取出在室溫環境中放置5min,再放置150℃的高溫箱中恒溫保持0.5h,取出在室溫環境中放置5min,如此往復5個循環。試驗完成后,產品性能指標應符合下列規定: Sample thermostats are placed in the constant-temperature box with temperature of -20℃。When temperature inside levels off,keep it for 1h..Then take the saples out and place for 2h.And then place them in the constant- temperature box with the temperature of 150℃,keep for 1h after temperature levels off,and take place for 2h.Finally,keep the samples in the constant- temperature box of -20℃for 0.5h,then take out an place them in room temperature.(5 min as one circle,and for 5 circles in a row) When experiment finished,samples should accord with the following guideline of specifications: ?動作溫度100℃以下對試驗初始值容許偏差再加上±5℃,100℃以上為±5% ?在標準大氣條件下,采用DC500V絕緣電阻表以額定電壓測試≥100MΩ。 ?在標準大氣條件下,采用1000V 50Hz的交流電壓施加于引出端與地之間1min,無擊穿、飛弧、閃絡。 ?Initial value of experient caused by action temperature:<100℃:±5℃;≥100℃±5%; ?With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ ?Parts between electriferous compenets and non-electriferous ones can bear 1000V 50Hz Hz AC current,which is nearly sine wave,for one minute as bearing test.Resulted no breakdown,no flashover. 5.4耐潮濕 Dampness Resistance 將產品試樣按GJB360.6規定置于溫度40±5℃、相對濕度90~95%的恒溫恒濕箱中48h后,產品試樣應符合下列性能指標: Samples thermostat are sealed in the instrument (conatant temperature & constant humidity),detailed as temperature of 40±5℃relative humidity of 90~95%,as per regulations of GJB360.6.After placed for 48,the samples should accord with the following guideline of specifications: ?動作溫度100℃以下對試驗初始值容許偏差再加上±5℃,100℃以上為±5% ?在標準大氣條件下,采用DC500V絕緣電阻表以額定電壓測試≥100MΩ。 ?在標準大氣條件下,采用1000V 50Hz的交流電壓施加于引出端與地之間1min,無擊穿、飛弧、閃絡。 ?Initial value of experient caused by action temperature:<100℃:±5℃;≥100℃±5%; ?With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ ?Parts between electriferous compenets and non-electriferous ones can bear 1000V 50Hz Hz AC current,which is nearly sine wave,for one minute as bearing test.Resulted no breakdown,no flashover. 5.5 耐振動 Vibration Resistance 將產品試樣剛性連接并固定在振動試驗臺上,相對上下、前后、左右各方向,避開產品動作溫度上下限±10以外,以頻率20~25Hz振幅3mm來回時間5min,歷時1h。試驗后,產品試樣應符合下列性能指標: ?Sample thermostats ars fixed on the surface of board with full intension.Then vibrate the samples with frequency 20~25Hz,swing3mm,come-and-go tine 5mm,in directions of fluctuation,front-back,left-righe,for 1h.After tested.The samples should accord with the following guideline of specifications: ?動作溫度100℃以下對試驗初始值容許偏差再加上±5℃,100℃以上為±5% ?在標準大氣條件下,采用1000V 50Hz的交流電壓施加于引出端與地之間1min,無擊穿、飛弧、閃絡。 ?Initial value of experiment caused by action temperature:< 100℃:±5℃;≥100℃±5% ?With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ ?Parts between electriferous components and non-electriferous ones can bear 1000V 50Hz AC current,which is nearly sina wave,for one minute as bearing test.Resulted no breakdown,no flashover. 5.6 耐跌落 Falling Resistance 將產品試樣從200mm高度自由跌落在水泥地、石板或鋼板等堅硬的水平面上,分別在各個方向跌落一次。試驗后,產品性能指標應符合下列規定: Sample thermostats fall down free,at the height of 200mm,to such solid horizontal like concrete ground,flagstone,armor plate.And falling begin respectively for one time,from the top,bottom,left,right,front and back.After experimented,the samples should accord with the following guideline of specifications: ?動作溫度100℃以下對試驗初始值容許偏差再加上±5℃,100℃以上為±5% ?在標準大氣條件下,采用DC500V絕緣電阻表以額定電壓測試≥100MΩ。 ?在標準大氣條件下,采用1000V 50Hz的交流電壓施加于引出端與地之間1min,無擊穿、飛弧、閃絡。 ?Initial value of experient caused by action temperature:<100℃:±5℃;≥100℃±5%; ?With a DC500V megger,borne DC 500V,the tested value is over 100 MΩ ?Parts between electriferous compenets and non-electriferous ones can bear 1000V 50Hz Hz AC current,which is nearly sine wave,for one minute as bearing test.Resulted no breakdown,no flashover. 5.7 觸電溫升 Contacts’ Temperature Raised <40K Less than 40K 5.8 可彈性 Solderability 波峰焊接:將波峰焊爐設置溫度最大260±5℃,將產品試樣進行預熱,預熱溫度≤150℃/1min,然后將產品試樣引腳進行就焊接,焊接時間≤7秒。手工焊接:用≥60W電烙鐵,烙鐵表面溫度≥280℃,單個引腳焊接時間≤15秒。 Wavrsolder process:Pot Temperature max 260±5℃. Pre-heating Temperature ≥150℃/1min. Terminals solder.Solder time≤7s.Ramp-down rate≤7℃/s .Soldering iron≥60W.Temperature≥280℃ Solder time≤15s. 6.1注意事項 Cautious u產品應工作于空氣相對濕度<90%,無腐蝕性氣體、可燃性氣體和導電塵埃存在的環境內; The thermostat should work in environment with humidity not higher than 90%,free of caustic,flammable gas and conducting dust. u產品安裝時,應使安裝板(金屬板)緊貼所控器件的發熱部位,并應在安裝板涂上導熱 硅膠或其他性能類似的導熱介質; When the thermostat is used to sense the temperature of solid items,its cup should be clung to the heating part of such items.Meanwhile,heat-conducting silicon grease,of other heat media of similar nature,should be applied to the cup’s surface. u任何情況下不可使產品變形,以免破壞產品電氣連接、溫度特性及封閉性; Must be kept out of the thermostat Characteristic it will influence temperature dependability of electric u使用過程中不可折彎引線腳,以免破壞電氣連接的可靠性; Terminals should not be inflected,of else,it will influence the dependability of electric connection.

東莞市富寬源電子有限公司(東莞市富源電子科技有限公司)成立于1998年,主要從事安規元器件生產和銷售,通過10年的改革和努力現在的富寬源已經成為集生產和銷售為一體的安規元器件總匯;富寬源將繼續秉持品質第一、服務客戶的原則不斷為廣大客戶提供質優價廉的產品。我公司目前主要提供如下產品:

電流保險絲-CurrentFuse

玻璃管電流保險絲

陶瓷管電流保險絲

貼片電流保險絲

電阻式保險絲

微型電流保險絲

高壓電流保險絲

直流電流保險絲

交流電流保險絲

SMD-貼片式自恢復保險絲

AI-插件式自恢復保險絲

保險絲座-Fuseholder

ESTMF系列保險絲座

EDKFH系列保險絲座

SKPTF系列保險絲座

AUTO--汽車保險絲座

OPWOP系列保險絲座

拉線盒式保險絲座

保險絲夾&端子

保險管座

保險座

大電流|高壓保險座

溫度保險絲-Thermalcutoffs

方塊形溫度保險絲

電阻式溫度保險絲

大電流溫度保險絲

陶瓷溫度保險絲

鐵殼溫度保險絲

SW.C溫度保險絲

NEC溫度保險絲

艾默生溫度保險絲

內橋溫度保險絲

松下溫度保險絲

AUPO溫度保險絲

溫度開關/溫控器-Thermalprotector

熱保護器/可恢復溫控器

風筒式溫控開關/溫控器

馬達熱保護器/溫控器

除霜除濕溫控器/溫控開關

超低溫溫控開關/溫控器

微型溫控開關/溫控器

溫度開關/溫控器-Thermalprotector

7AM/17AM溫控器

KSD301系列溫開關

KSD-01F插腳溫開關

9700系列方塊形溫控開關

BR系列溫控開關

SEKIST-22溫控器

壓敏電阻-Varistors

壓敏電阻

氧化鋅壓敏阻器

貼片壓敏電阻

SMD壓敏電阻

插件型壓敏電阻

高能壓敏電阻

汽車保險絲Autofuse/carfuse

小號汽車插片保險絲FY-MIN

中號汽車插片保險絲FY-ATC

大號汽車插片保險絲FY-MAX

小號叉栓式汽車保險絲FY-UF

大號汽車叉栓式保險絲FY-MF

管狀|柱狀汽車保險絲

其他型號汽車保險絲

過載保護器-CIRCUITBREAKER

AR1/AR2系列過載保護器

W系列過載保護器

88/88A系列過載保護器

90系列過載保護器

91/91L系列過載保護器

97/98/98H系列過載保護器

帶開關系列過載保護器

熱敏電阻-NTC/PTCThermistor

負溫度系數熱敏電阻

陶瓷正溫度系數熱敏電阻

高分子正溫度系數熱敏電阻

溫度傳感器

濕度傳感器

本公司將繼續通過ISO9000質量管理體系的有效實施,使涉及企業生產經營的各個運作環節,均嚴謹有序,不斷制造出質優價廉、適銷對路的產品參與市場競爭,使企業長期保持較強的經營獲利能力。同時我們將長期重視與行業知名企業合作,爭取最大限度的代理權,以最優惠的價錢把產品銷售給客戶。

|

--------------

--------------